Product Details

Shuoer Machinery has a complete range of precision punching machines, including 3 ton -15 ton desktop small precision punches, 15 ton to 400 ton frequency conversion energy-saving steel frame precision punches, 400 ton to 1500 ton large gantry type punches, three-round guide column high-speed punches, Toggle link high-speed punch presses are all produced. Shuoer C1N series steel frame precision punch presses have undergone many technical improvements on the basis of the old H1N series medium-speed punch presses. The punching equipment has stable performance, small die height changes and small dynamic center deviations. , The mold life is greatly improved, the deformation of stamping is small, the noise of cutting and cutting is small, the operation is more convenient, the fixed-locking six-sided guide path, the high-rigidity body, the low comprehensive clearance and other advantages. Energy saving, frequency conversion, simplicity, intuitiveness, and digitization are the direct manifestations of this series of presses. C1N series punch presses have won praises from many customers for their high precision, high speed, high stability and high cost performance over the past ten years. They are the hot-selling models of Shuoer Machinery.

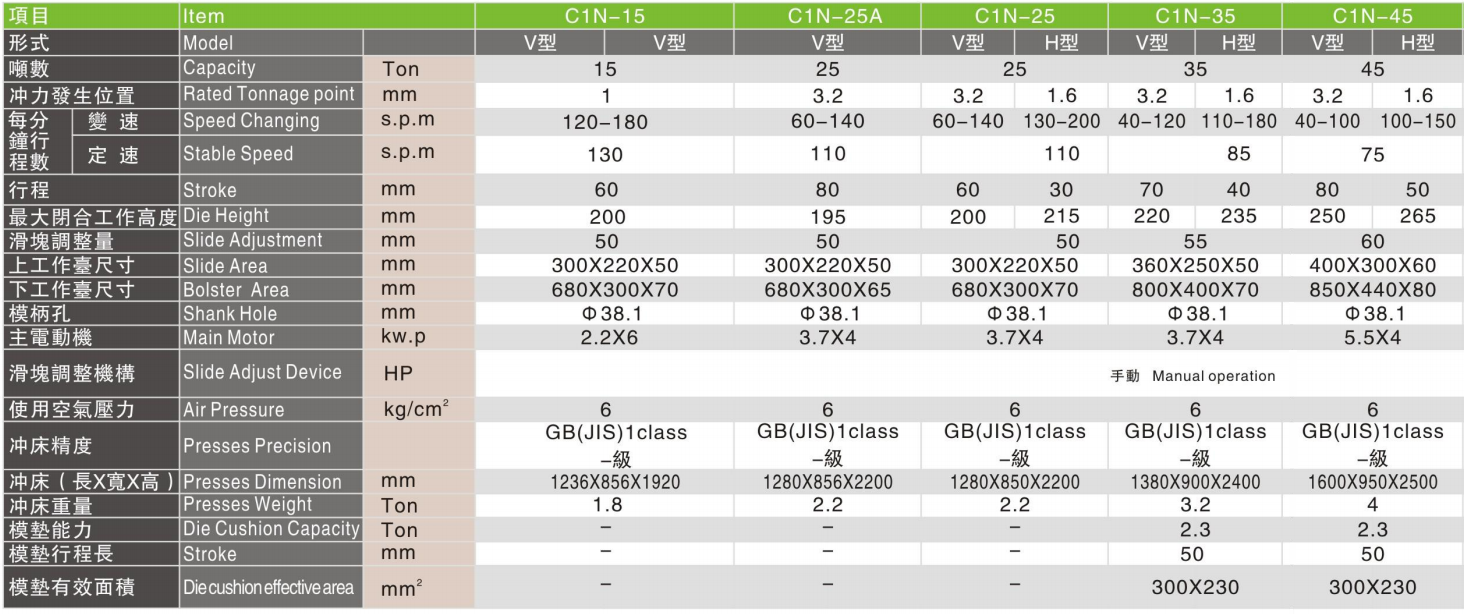

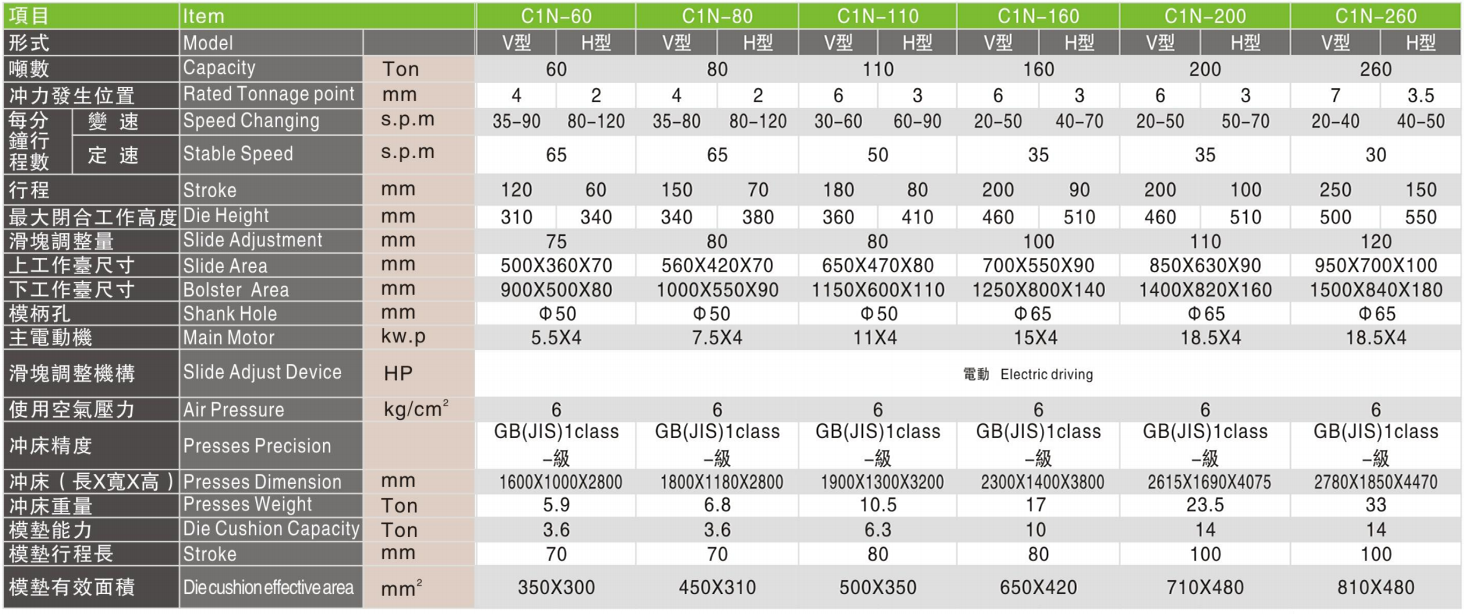

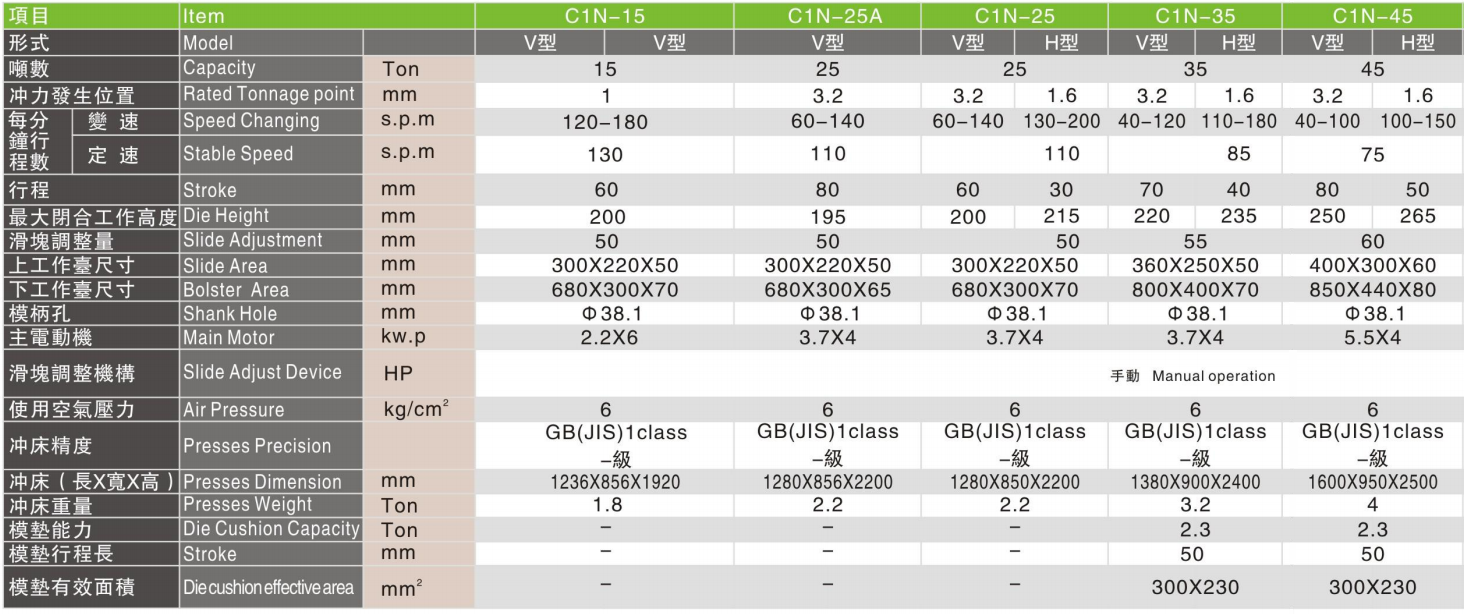

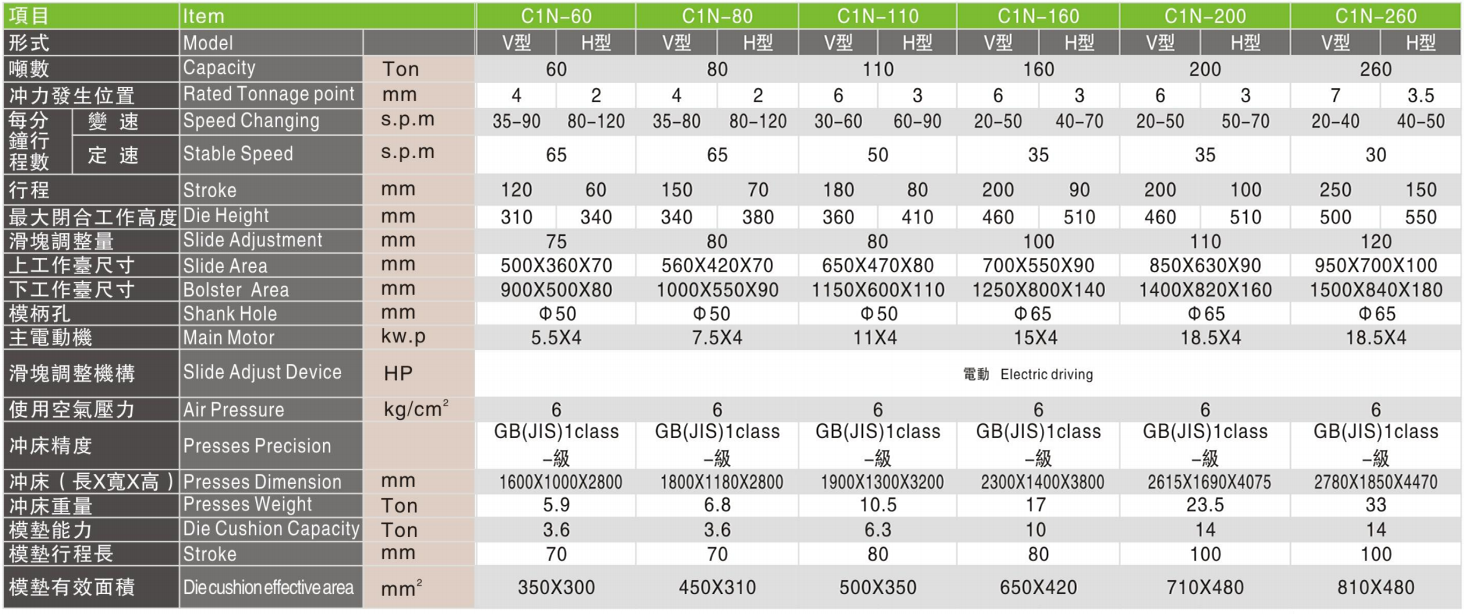

Shuoer Machinery's high-precision and powerful steel frame punching machine model range: C1N -15~260 Tons (large tonnage non-standard type can be customized according to needs)

Application range: C1N (high precision and powerful steel frame punch)-widely used in stamping and forming of electronics, communications, computers, household appliances, vehicles (automobiles, motorcycles, bicycles), hardware parts, etc.

Shuoer precision punch C1N series are divided into: 15T, 25T, 35T, 45T, 60T, 80T, 110T, 160T, 200T, 260T, with complete product specifications, suitable for stamping and processing of multi-material products in various industries.

Model features:

1. Security

Continuously improving the active safety of the press is SR's long-standing belief, always providing users with the safest and most reliable experience. This concept is fully experienced in the C1N series.

2. Brake

All C1N series discs are equipped with advanced dry brake clutches, coupled with the precise and sensitive double solenoid valve from Japan TACO can shorten the braking time to the greatest extent. In addition, the brake assist system's second fall device in an emergency, when it detects that the brake cannot stop, it will provide a brake signal again to provide a brake signal again to provide sufficient power to ensure timely and accurate braking.

3. User protection

In the design stage of the C1N series, the highest degree of user protection is also the biggest goal of SR. Therefore, leave enough space between the two-hand operation buttons and between the fuselage to protect the safety of the hands. At the same time, the system design stipulates that both hands can be operated at the same time to ensure that no personal injury caused by misoperation is allowed. The addition of photoelectric protection devices or protective nets further improves the protection of users.

4. Mold protection

C1N series punch presses are equipped with imported overload device as standard to protect the punch from deformation and damage of the mold due to overload stamping. At the same time, it is also equipped with a misfeed detection device that can cooperate with an automatic stamping die device to better protect the mold.

5. Robustness and durability

Shuoer has developed a new generation of high-strength rigid body for the C1N series. The motherboard has been reinforced. There are reinforced support plates from the motherboard, side panels and worktables, which can effectively absorb vibration energy to eliminate vibration from all directions. The impact and vibration of the machine protect the stability and safety of the punch.

6. High-quality materials

All materials of Shuoer SR in the C1N series are the highest level of similar products. For example, the main board is Baosteel, the crankshaft is 42CrMo, etc. The hardware components are basically imported high-quality products, such as bearings are all imported from Japan. .

7. More precise and stable

All parts (including the fuselage, crankshaft, slider, etc.) have undergone various processes, such as stress relief, to ensure the stability of product accuracy.

8. High precision density

The gears, crankshafts and other components on the Shuoer series are all precision-grinded, and the main parts of the products are all imported high-end CNC processing equipment, production, and accuracy, so that the whole machine can reach the Japanese first-class accuracy standard.

Technical parameters of C1N series high precision and strong steel frame punch (15T-45T)

Technical parameters of C1N series high precision and Strong steel frame punch (60T-260T)

Español

Español عربى

عربى Português

Português हिन्दी

हिन्दी Tiếng Việt

Tiếng Việt にほんご

にほんご English

English 中文

中文